Products

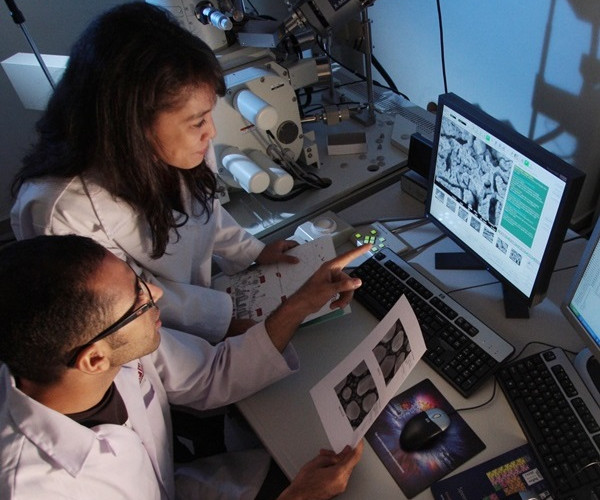

We offer a variety of standard specification hardmetal powders commonly used in the hard-facing component manufacture and the maintenance, repair and overhaul (MRO) industry. Our range of ready-to-order powders are optimised for use in a variety of metal additive manufacturing (AM), thermal spraying and metal injection moulding equipment.

If the standard hardmetal powder you’re looking for is not on our list, please contact us for our materials available on request.

Our Powder Range

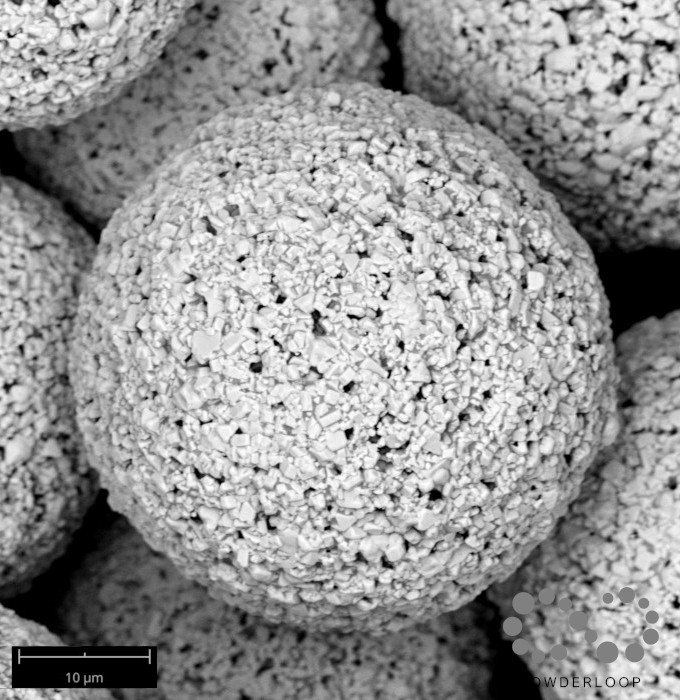

PowderLoop supplies a range of hardmetal powders specifically developed for HVOF and metal AM processes. Tungsten carbide coatings are the most frequently applied wear resistant surface treatments, typically used for extreme wear conditions. Chrome carbide coatings, on the other hand, offer excellent oxidation resistance at higher temperatures and under corrosive or oxidising conditions.

Tungsten Carbide Powders: WC-10Co-4Cr, WC-12Co, WC-17Co, WC-9Co-5Cr-1Ni, WC-WB-Co, WC-20Cr3C2-7Ni, and WC-10Ni-5Cr.

Chromium Carbide Powders: Cr3C2-20NiCr, Cr3C2-25NiCr, and Cr3C2-WC-NiCr.

Alloy Hardfacing Powders: NiCrAlY, CoCrAlY, NiCrBSi, and NiCrFeBSi.

Custom Hardfacing Powder: We offers custom development of hardmetal powder, tailored to your mechanical property needs, from early-stage to pilot and full-scale applications.

Applications

Hardmetals are widely applied both as bulk materials and as protective (hardfacing) coatings. While conventional Thermal Spraying and Hot Isostatic Pressing remain the industrial workhorse, metal additive manufacturing (AM) is finding its niche in expanding applications over the past decade.

Metal AM covers a group of emerging technologies using metal powders to create complex 3D components, such as Powder Bed Fusion, or to form hard-facing coating, such as Directed Energy Deposition.

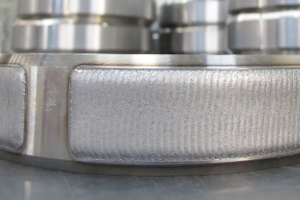

Directed Energy Deposition

DED, or laser cladding, is the most used AM process at industrial level. Unlike thermal spraying processes, DED coating is metallurgically bonded to the substrate, and offers better powder usage (deposition) efficiency up to 90%.

Powder Bed Fusion

PBF is a process by which a 3D part is formed from the successive addition of 2D layers of powder selectively fused together, using laser or electron beam, in pre-defined geometries. No tooling is required making PBF a very versetile process.

Thermal Spraying

Thermal spraying, in particular High Velocity Oxygen Fuel (HVOF), is the most widely used techniques of surface treatment against wear and corrosion. HVOF coating is high density, low oxide content and excellent bond strength to the substrate.

HIP / MIM

Hot Isostaic Pressing and Metal Injection M0ulding are two commonly used technologies for mass production of cemented carbide inserts, dies, punches, rods etc. Hardmetal powder is compressed into a mould of predefined geometry by applying high temperature and pressure simultanneously.